Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the Australia Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Meeting the requirements of industrial vacuum heat treatment standards is easier with accurate control of temperature and vacuum pressure.

DownloadChoose from a range of control solutions designed to help you achieve:

• Surface hardness specifications

• Conforming microstructure

• High quality finish

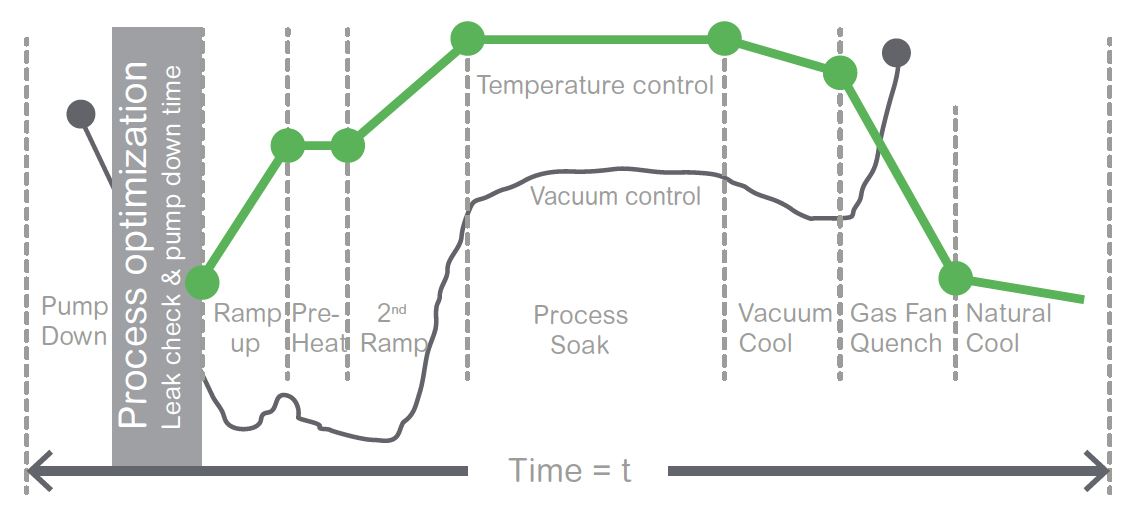

Optimize cycle times, and record the process to meet heat treatment data regulations.

Features:

• High vac / low vac control

• Furnace temperature control

• Setpoint programming

Associated products:

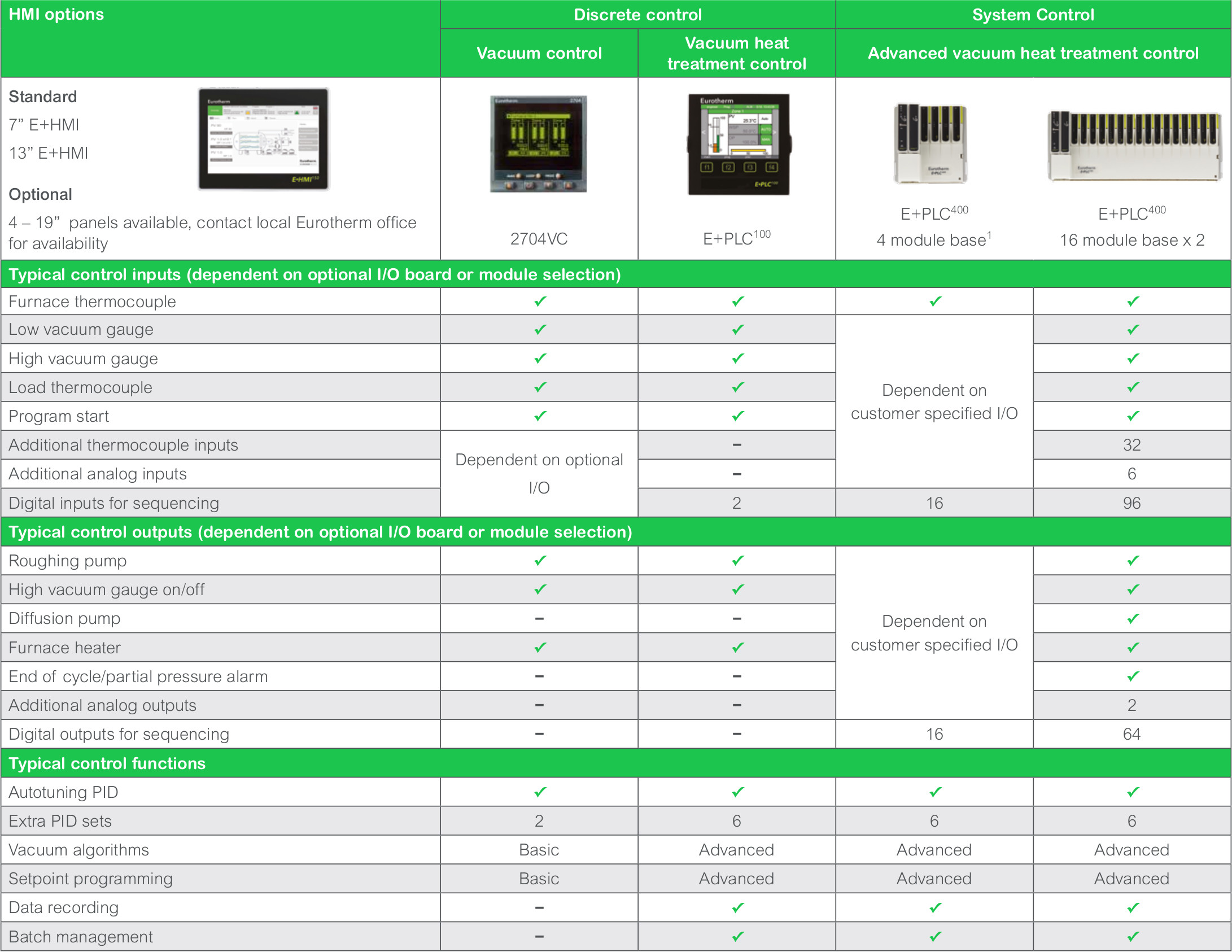

Vacuum control

Provides multi-setpoint control via a setpoint program and sequencing of the vacuum pumping system, with bumpless transfer between low vac and high vac gauges.

Find out more

Features:

• High vac / low vac control

• Furnace temperature control

• Load thermocouple inputs

• Setpoint programming

• Inbuilt trend and tamper resistant data recording

Vacuum HT control

Provides multi-setpoint control via a setpoint program and sequencing of the vacuum pumping system, with temperature cycles.

Provides multi-setpoint control via a setpoint program and sequencing of the vacuum pumping system, with temperature cycles.

Features:

• High vac / low vac / partial pressure control

• Furnace temperature control

• Load thermocouple inputs

• Quench gas control (gas type/pressure)

• Setpoint programming

• Inbuilt trend and tamper resistant data recording

• IIoT (Industrial Internet of Things) ready

• Easily integrated with 3rd party PLCs (hybrid system)

Advanced vacuum HT system control

Setpoint control as above, plus leak-rate detection and pumping-time systems to aid the optimization of cycle-times. This IIoT ready system also allows enhancement with predictive maintenance functionality.

Find out more

The thermocouple linearization function block converts the mV input reading and cold junction temperature into a temperature output. It also provides scaling, low pass filtering, offset and manual-override capabilities.

Provides a channel output to control a process variable (PV), using a precision PID control algorithm designed by Eurotherm. Autotune is included, as well as a ‘cutback’ feature to control overshoot behavior. A gain scheduling feature is available for adding extra PID tuning sets, to help maintain tight control at different setpoints.

Derives the working lifespan of thermocouples in days or number or times used, under different ranges of operating temperature. The block monitors usage times and temperatures, and indicates whether the thermocouple is still valid for use according to the AMS2750E standard.

* Available in E+PLC only

Converts raw electrical measurements into vacuum pressure values. It also supplies a gas calibration factor for non-N2-type atmospheres, low pass filtering, offset, and manual override. Provides vacuum gauge linearization for several common vendors, as well as user defined linearization capability.

Allows for smooth (bumpless) switching between a “low” vacuum gauge, such as a Pirani gauge, and a “high” ionization type such as an inverted magnetron or Penning gauge.

Optimizes vacuum cycle time by alerting operators to a controller detected event or leak in the vacuum system. It can be configured to signal an alarm if a particular vacuum pressure has not been reached in a given amount of time.

Implements a leak test strategy for a vacuum chamber, using industry standard leak-rate methodology

1.E+PLC400 with any number of modules from zero upward can be used to create a hybrid advanced vacuum heat treatment control system, in combination with Schneider Electric, Eurotherm and 3rd party PLCs.

Product I/O options shown are for example only. Contact your local Eurotherm sales representative to discover the most suitable solution for your process.

Contact Us >Scalable integrated systems and services, from single machine to enterprise solutions, including:

• Power control (SSR/SCR) and process control

• Data management, alarm management and supervisory systems

• System design, engineering and installation

• Calibration and maintenance services

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us